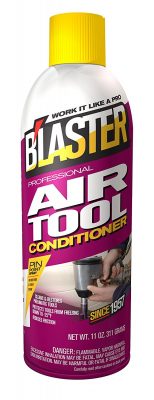

Calcium build up can occur as water evaporates in tools. Air Tool Conditioner (16ATC) returns a tool to normal speed and power by breaking the surface tension of minerals in the tool. Once per week is standard unless the tool is used frequently.

Calcium build up can occur as water evaporates in tools. Air Tool Conditioner (16ATC) returns a tool to normal speed and power by breaking the surface tension of minerals in the tool. Once per week is standard unless the tool is used frequently.

Drain Tank/Filters

Moisture is condensed in air under pressure in the air lines and at the bottom of the tank. A compressor can make nearly 18 gallons of water vapor a day under average conditions of 75 degrees with 75% humidity. Your tools will experience loss of power, early failure, and potentially seize up with rust down the line as water moves through your system.

Keep Tools Clean

Protective covers can reduce wear/damage caused by abuse or dropping of air tools. When a tool is dirty it can decrease power and the life of a tool.

Beat up impact tools and sockets significantly reduce the life of tools. Sockets won’t fit correctly if the beveled portion of the tip of the shank is worn. A loose or improper fit rounds the socket’s opening and once the socket is rounded it will wear the bevel quickly on the shank of a new tool similarly. Best practice is to purchase new sockets with a new wrench.