Why do you need to replace stems and kits with TPMS?

We all know we are supposed to do it, but do our customers understand? It is our job to ensure they know and follow the laws.

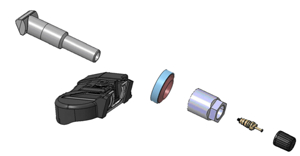

Remember, replacing the TPMS valve stem (snap-in rubber or clamp-in aluminum) or the TPMS service kit with each tire sale is done for the same reasons a traditional TR-413 snap-in is replaced with each new tire. You need to make sure you abide by these guidelines.

- Replace the nickel-plated valve core every time a tire is removed or mounted.

- Valve cores have rubber that can degrade and can get damaged over time.

- If the sensor is removed, the grommet or O-ring should be replaced.

- When you tighten down on the grommet the rubber creates a seal with the surface in imperceptible groves that can never be matched up perfectly again after removal.

- Always check and use the correct torque for tightening the valve stem nut. Some call for 35 inch-pounds, and failure to set the wrench correctly will be a costly mistake.

The links below illustrate issues where improper TPMS service created serious problems in an investigation in California. This is in regards to TPMS service kits and valve stems.

https://abc7news.com/news/7-bay-area-firestone-shops-accused-of-fraud/1404430/

https://www.bar.ca.gov/pdf/accusations/ard222633_2015_12_07_amended_acc.pdf

Check out why from Dill: